Paper industry

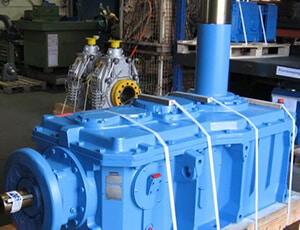

The paper industry is our second home. From a drive perspective, we offer everything from a single source. Starting with engineering and continuing through designing the drive to assembling and commissioning all components. We are also the perfect point of contact in the cooling and lubrication technology sector for drive units. Furthermore, we also work on repairs in the paper industry. From the pulper to reels, we know all types of gearboxes and repair them.

Drive services for the paper industry

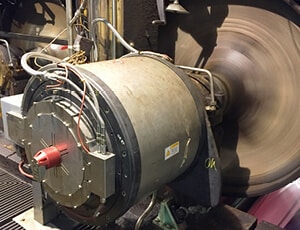

We have been active as a repairer of gearboxes from all manufacturers in the paper industry for more than 30 years. We inspect gearboxes along the entire production line. Starting with the barking plant and continuing through source material preparation, agitators, couch rolls, presses and cylinder drives to reels and cutting systems.

Innovative products for the paper industry

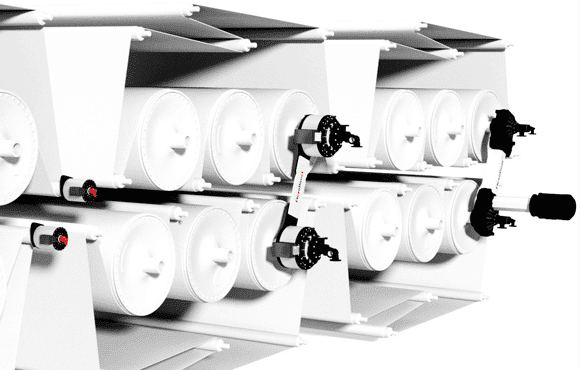

Our many years of experience in gearbox repairs has prompted us to develop innovative solutions for recurring problems. We started with our own range of gearboxes for drying groups. We developed our own lubrication system for suitable lubrication and a fully-automated flow rate controller for distributing oil.

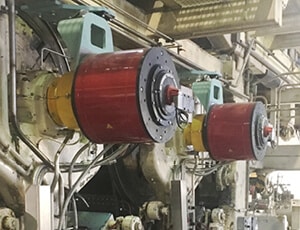

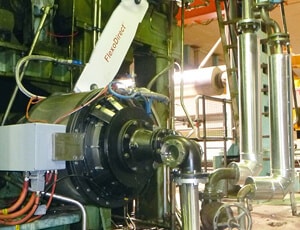

In addition to the mechanical drives, AS brought its own motor-drive range for the entire paper production line onto the market. In the dry section sector, we are therefore the only supplier to offer a direct motor that can be installed on the drive side together with the steam head on the cylinder journal. Suitable cooling units and flow rate controllers for the cooling water flow complete this motor package.

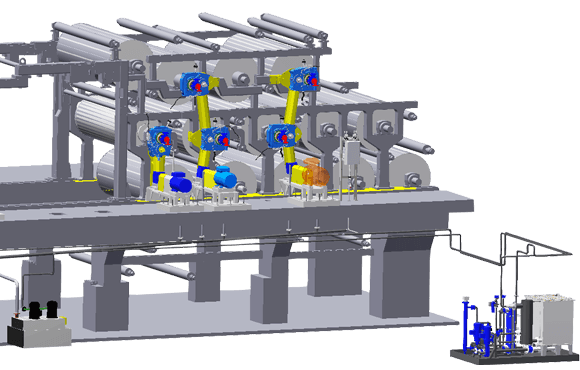

Turnkey solutions for the paper industry

Our engineering department plans all modifications and draws up drive and lubrication concepts for complete turnkey modifications of paper machines.

We draw up solution concepts for modernisation, modification or complete re-equipment of complete systems and partial areas such as the drying groups. Speed increases, reliability improvements for the drives and reducing downtimes for old, outdated drives are the reasons for this.

Our engineers draw on both our own drive and lubrication solutions and on standard solutions. Whichever makes the most sense for the relevant application.

References

Maintenance

Ekato Agitator gear

Hansen vertical pulper

Renk feed gear

Santasalo pulper

Santasalo pulper

Metso Drainage press

Flender dryer drive

Metso DRG gearbox

Metso DRG gearbox

Flender yankee drive

Valmet gearbox

Tambour coupling in two parts