Perfect oil treatment

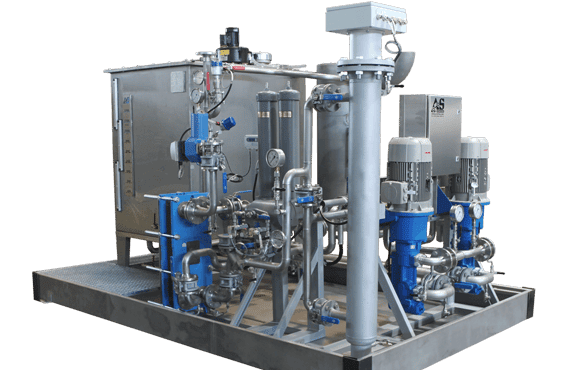

The Lubriflex® is ideal when it comes to treating lubricating and cooling oil, as it has everything “on board”

that is required to clean, de-gas and temper your operating oil.

Lubriflex® conditions oil

The Lubriflex® is supplied ready for connection with all necessary components, from the degassing tank to filters for suspended particles and the heater for heating the oil. On request, the Lubriflex® can already be supplied with integrated control technology. Thus, the Lubriflex® is ready for operation directly after integration into the pipe system. The Lubriflex® can be used in new plants as well as a replacement for existing oil circulation lubrication systems. Only an inspection of the existing piping system is necessary. A possible new piping as well as the final leak test can be carried out by AS.

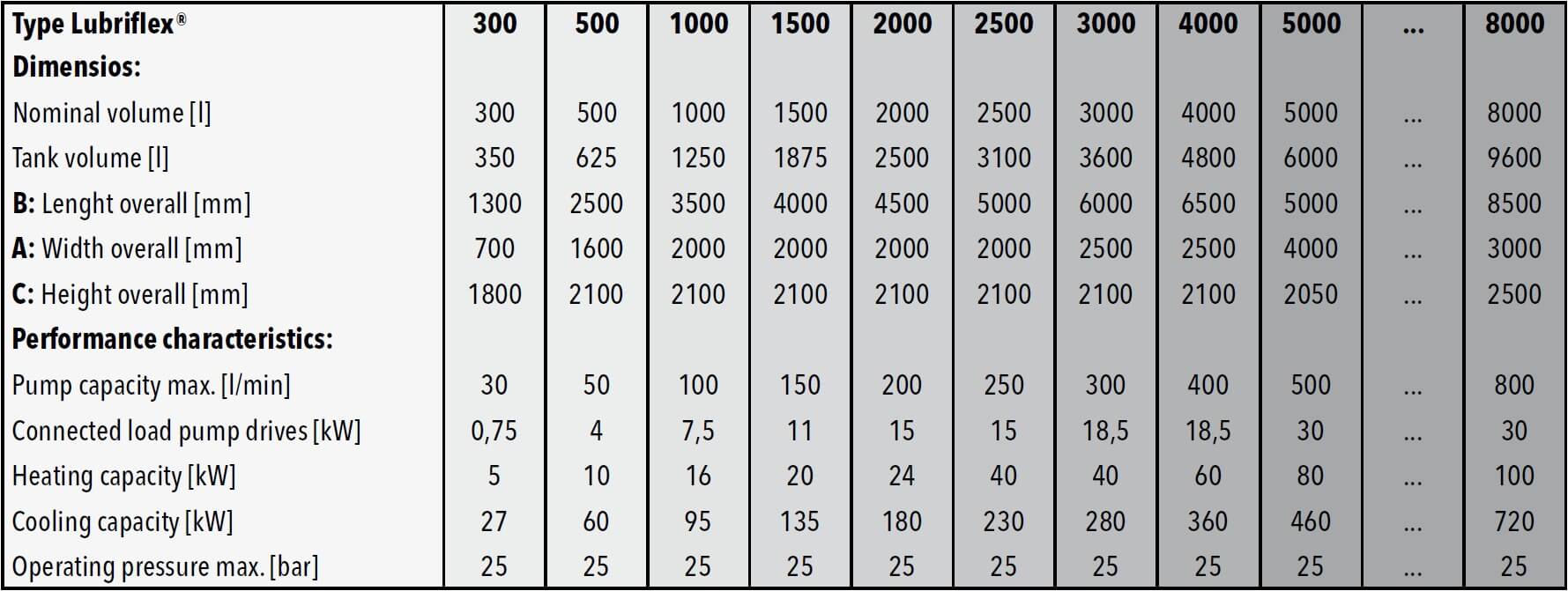

Series

There is the right Lubriflex® for every application. We use the oil requirement to calculate the optimum tank size.

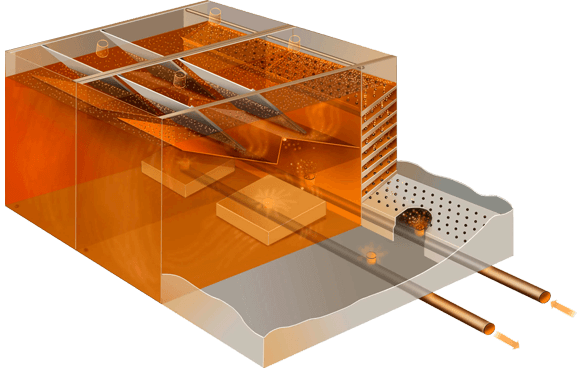

Flow course

Lubriflex® assures optimum degasification, cleanliness and operating temperature of the lubricant. A special degasification system minimises the oil dwell time and this halves the container volume.

Removable flow direction channels make the complete interior easy to clean. The redundant design of the most important components (e.g. the pumps) creates a very high level of machine availability.

The advantages at a glance

- Degasses, cleans and brings the oil to the correct operating temperature

- Optimum degassing properties

- Minimising the tank volume