reliable motor cooling

The Cooliflex® keeps motors at temperature

The Cooliflex® was specially developed for the temperature control of water-cooled components (motors, converters, plant components). The cooling water circulates in a closed circuit between the cooling points and the Cooliflex®. Of course, several consumers can be connected to each Cooliflex® – distribution to these consumers can take place directly on the Cooliflex® or in the field with our FlexoFlow® registers.

The Cooliflex®

The Cooliflex is designed as a plug-and-play system: Set it up, connect the power supply and fill up with coolant. All control components are fully assembled, tested and “ready to use”. No external control is necessary. Various proven control algorithms are immediately available to implement functions such as constant temperature, constant flow or adaptive control of the fresh water temperature. The integration into a DCS can of course be carried out via PROFIBUS, PROFINET or – if only a simple feedback is required – digitally. This means that a higher-level master can visualise the plant as desired or control it remotely. The components of the plant are generally corrosion-resistant. All important pipeline routes in the Cooliflex® are equipped with bypass lines, so that the maintenance of individual components is possible during operation. Redundancies in the control system and in the pumps ensure operation in the event of a fault. For example, pumps, the heat exchanger (available as a water-air or water-water system) or electrical components can be replaced during operation.

Sizes

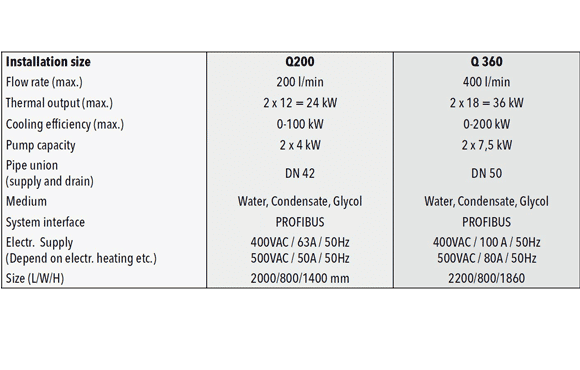

Basically two sizes of Cooliflex® are available.

Integrated heat recovery function

In order to further improve the overall energy balance of a system, it makes sense to use the waste heat for downstream processes (preheating, spray pipes, hot water). This energy utilisation is only effectively possible if the temperature of the medium is sufficiently high. With AS systems, the motors can be cooled depending on the respective load point. The temperature difference of a cooling point receives all necessary information for the condition analysis – an adjustment of the mass flow in dependence of this information ensures a constantly high and well usable return flow temperature. The average cooling water temperature at the plate heat exchanger of an AS drive system with FlexoDirect® for the drying group of a paper machine is thus always in the range of 60-70°Celsius.

The advantages at a glance

- Temperature control of motors

- Closed cooling water circuit

- Energy saving through frequency-controlled pumps