Service packages for industrial drives

Your machine is our drive

By drive services we understand more than just the pure repair of drive systems. With us you get everything that makes and keeps your drive ready for operation.

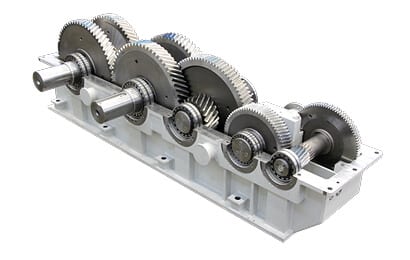

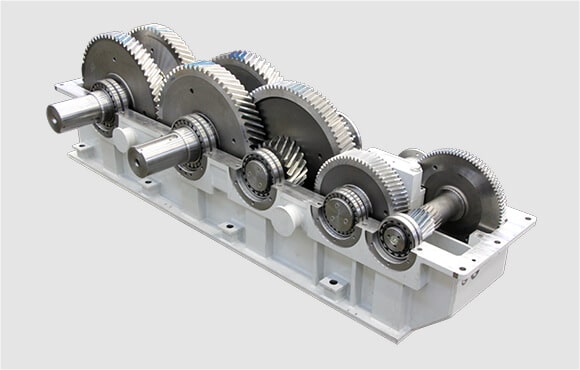

We repair gears of all manufacturers

Repair

We repair gears of all manufacturers!

Everything from a single source:

- Removal of the drive on-site

- Extensive damage analysis in consultation with the operating company

- Recalculation and redesign of the gearbox and gearbox parts by our own design department

- Modification of the gearboxes on the basis of the knowledge gained

- State of the art and professional assembly

- Re-installation on-site

ReDesign

By “ReDesign” we mean the type-independent new design or redesign of a gearbox.

Reasons for a redesign:

- The original gearbox manufacturer is no longer on the market

- The gearbox type is no longer built

- Increased circulating reserve due to one-off and small-batch production

- Modification of problematic drives

Improvement

AS checks drive concepts holistically for possibilities for improvement.

Reasons for improvement include

- Analysing recurring problems or

- Wanting a speed increase

AS will develop an optimisation concept for each gearbox. This concept will be checked, calculated and designed in our in-house design department according to the practical application.

Inspection on site

AS performs the gearbox inspections both when the machine is at a standstill and running (if possible).

All results of the inspection are recorded systematically and collated in comprehensive documentation that includes illustrations and handling recommendations. This documentation is the decision basis for planning further measures.

We are happy to compile solution strategies and repair methods together with you. Regular gearbox inspections also provide information on the status and development of a drive.

Drive installation

AS has well-trained staff and a comprehensive and tailored too system in order to be able to work flexibly and independently for customers. Our systems can be transported to the required location using industrial trucks or a crane. This results in extremely short paths to the work site.

Spare parts management

We supply all types of spare parts for gearboxes, including

- Bevel gear sets

- Spur gear sets

- Hollow output shafts

- Bearings

- Neck journal bearing bushes

- Couplings

- Labyrinth flanges/rings

- Housing

- And much more

Our design department designs the new spare parts, builds them and produces corresponding drawings and documentation based on component parts and with the aid of the performance data or the system data.