Always state of the art

Our products are aimed at customer uses and provide real added value. Each development is optimised for the relevant application situation. As a system solver for modernisation in the drive technology sector, we offer a wide product range. From new equipment for new systems and speed increases to removing and modifying outdated drive and lubrication components.

Discover the world of innovations with us in the field of drive and lubrication technology

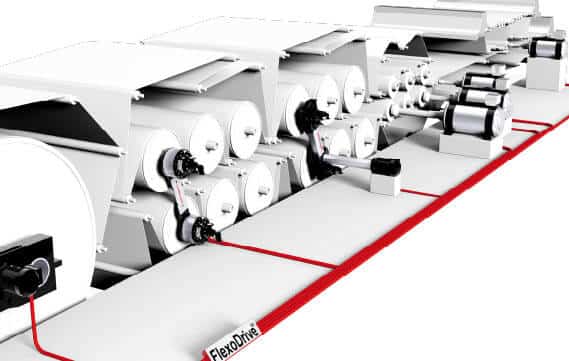

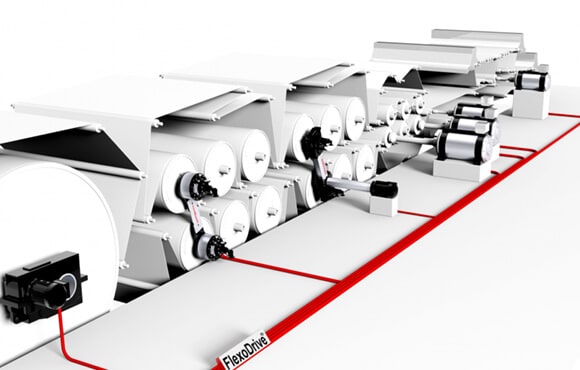

Direct motors

Engine construction with passion

As a motor manufacturer, AS accompanies every step of the design process for a drive unit – whether for modernisation or for a new-build. Starting with an analysis of the drive requirements, production of a requirement specification and design on the CAD system through to simulation of the drive and integration of it in commonly used control systems

Tempering units

Reliable motor cooling

The Cooliflex® was specially developed for the temperature control of water-cooled components (motors, inverters, plant components). The coolant water circulates in a closed circuit between the cooling points and the Cooliflex® unit.

Engineering

Turnkey-solutions for your machine

Depending on the machine, AS can always provide an appropriate drive solution, whether that involves increased speed, modernisation or the renewing of drivelines.

With its own engineering and design department, AS can devise customer-specific solutions. The very latest CAD programs make perfect planning possible as well as optimum visualisation of all construction components in 2D or 3D.

Flow controller

Precision made in Germany

The FlexoFlow® is the intelligent flow rate controller, made by AS. The FlexoFlow® is used wherever precise distribution of liquid media is required.

Depending on the version, it can adapt entirely automatically to suit different quantities of oil or water.

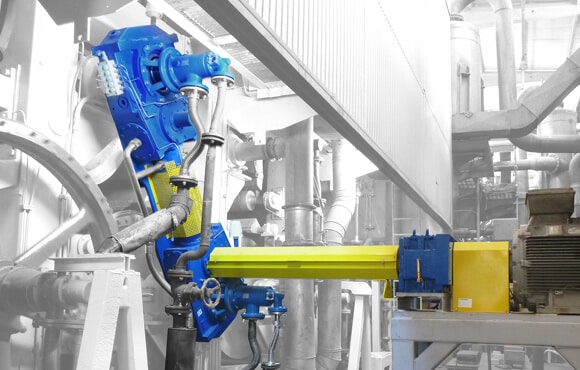

Gearboxes

The flexible concepts

The FlexoGear® gear series from AS has been specially developed for use on drying cylinders of a paper or board machine. In order to be able to absorb the torques, AS has developed a torque support which enables absolutely stress-free operation and makes a connection to the machine frame superfluous. The coupling of the gears allows the operation of up to 4 gears with only one drive motor.

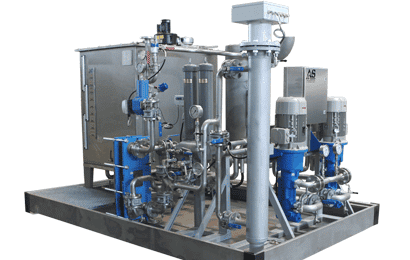

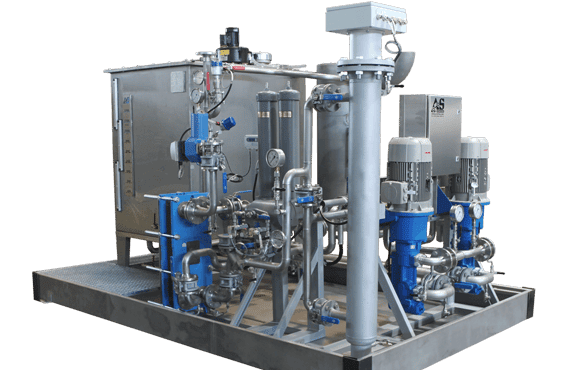

Lubrication units

Oil treatment at the highest level

The oil circulation lubrication system Lubriflex® has been specially developed for the optimum treatment of lubricating and cooling oil. It ensures optimum degassing, purity and operating temperature of the lubricant. A special degassing system leads to a minimisation of the oil dwell time and thus to a halving of the container volume.