Carefree allocation of oil and water

The intelligence that makes monitoring and adjusting liquid media so easy is in the FlexoFlow®. The FlexoFlow® is the appliance of choice in systems with many lubrication points and the requirement for exact lubricant or coolant distribution in particular. It replaces the simple monitoring devices and moves your system into the 21st century from a flow control perspective.

FlexoFlow® regulates

Once you have told the FlexoFlow® what quantity to adjust, the rest is child’s play. Regardless of pressure, temperature and viscosity, the FlexoFlow® now supplies your gearboxes and bearings with oil fully automatically. Bearing overflows are now a thing of the past. Overheating or falling below the dew point of motors are also a thing of the past. Because the FlexoFlow® can also supply cooling water according to the engine temperature. So you can sit back – your FlexoFlow® does the work.

Allocation of oil or water

Liquid media such as oil or water can be monitored and adjusted without problems using the FlexoFlow®. For example, lubrication points are supplied with lubrication or cooling oils, or motors are supplied with the corresponding cooling water.

Full control

“Communication” with the FlexoFlow® is either enabled via the system’s own touch panel or via a Profibus interface. All parameters (e.g. flow rate, alarm and switch-off times, etc.) can therefore be programmed easily. Alarm messages from the FlexoFlow® can also be read out at lightning speed and clearly in this way. You are therefore in full control over all lubrication and cooling points.

Variants

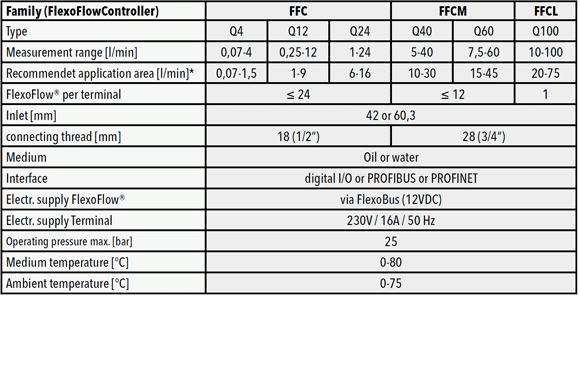

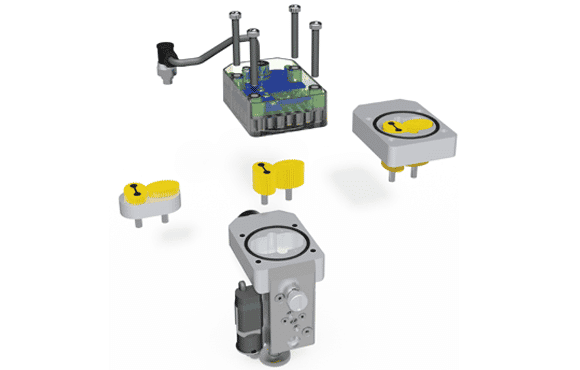

In order to cover virtually all flow ranges and to still be able to react flexibly, the FlexoFlow® has a modular design. Just a few basic housings are required to cover a measurement range of 0.07 – 100 l/min. Easy to change oval wheels and the use of adapters make the FlexoFlow® a multi-talent with regard to measurement range coverage. This reduces the number of spare parts kept in stock enormously.

Connected intelligence

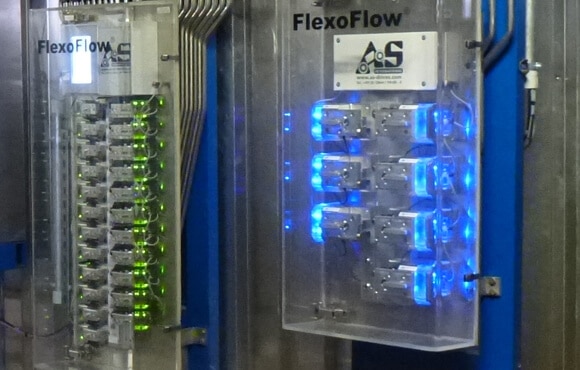

The FlexoFlow® terminal is the central connection station for the FlexoFlow® unit. All components are connected to a central supply unit. Inside the system, the FlexoFlow® units then adapt their settings simultaneously and independently of one another.

All relevant data can be entered via the so-called FlexoPad for every FlexoFlow® unit (or for entire groups of FlexoFlow® units) and interrogated (does not apply FlexoFlow® Display). For the input and output of data, the FlexoFlow® terminal can either be used with the process control system via PROFIBUS, PROFINET or via I/O card.

For the various operating points of a system, individual specified values can be entered for every FlexoFlow® unit or for a complete FlexoFlow® terminal. For example, the amount of oil required in ‚crawler speed‘ is reduced. At the touch of a button, or controlled automatically by the PLC, the flow rate controller can be adjusted up or down a ramp to the appropriate stored value. Through progressive adaptation of the oil quantities it is possible to avoid bearing overflows after a cold start.

Modular design

The FlexoFlow® is based on a modular design which means that the same basic housing is able to cover a very wide range of different measuring ranges. This is achieved through the use of various sizes of oval wheel and corresponding adapters, reducing the inventory level of spare parts for the various different areas of application.

The advantages at a glance

- simultaneous feedback control of all lubrication points in the system

- no problem to add and expand existing lubrication systems even possible to convert just one assembly group at a time

- pump system pressure can be reduced

- power saving

- protection of all components (pump, filter)

- minimal need for pipework.