We cement our good reputation as a professional

Cement industry

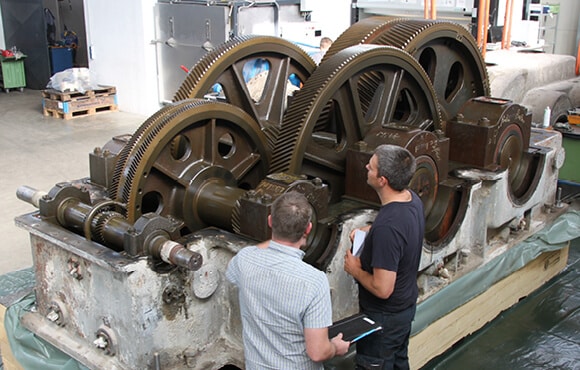

AS repairs virtually all gearbox types that are found in the cement industry. For example, gearboxes for crushers, belt conveyors, bucket conveyors, mills, resonance conveyors and rotary kilns. As we have been active in the cement industry for many years, the requirements and challenges in this sector are already well known to us. In order to always be able to offer a solution that meets the requirements and that is economical, we maintain close contact with our customers.

On-site gearbox inspection

AS performs the gearbox inspections both when the machine is at a standstill and running (if possible).

All results of the inspection are recorded systematically and collated in comprehensive documentation that includes illustrations and handling recommendations. This documentation is the decision basis for planning further measures.

It forms the optimum basis for deciding on any pending require repairs, and for planning and performing these.

Unexpected machine downtimes can be prevented and availability increased.

Drive services

We are happy to inspect gearboxes on-site and to repair them. We can process gearboxes with a total weight of up to 40 tonnes without problems in our workshops.

And we’ll even find a solution if things get difficult.

Whether it’s installing new bearings, reworking or a new delivery, everything is just a question of the damage and consulting the customer.

What else can we provide specifically? Simply click the following button.

References

Maintenance

Double unbalance gearbox

Flender 2 SH 21 A Conveyor belt drive

Flender DD 300 Rotary kiln drive

Flender DTLW 1720

Flender KMS 630 Mill drive

Lohman Stoltefoht Beater Mill

PIV Variable speed gear FAB 22

Renk STK 75-0