Customised solutions

Flexibility and experience characterise our design department. All of our designers have a sound technical and craftsmanship training and know what is important.

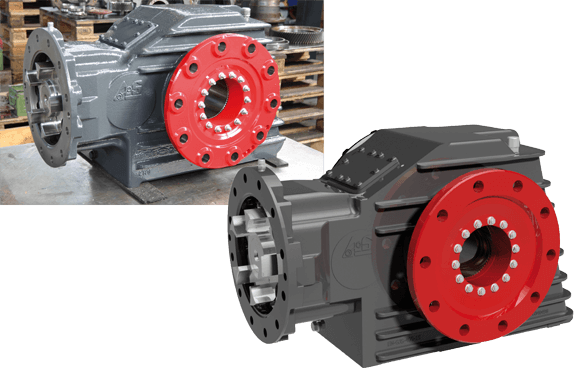

ReDesign of industrial and railway gearboxes

By “ReDesign” we mean the type-independent new design or redesign of a gearbox.

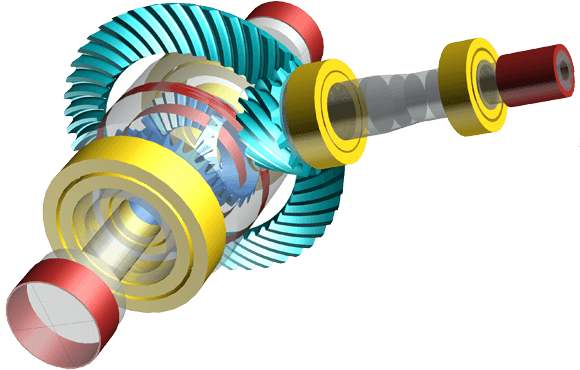

Performance check and recalculation of gearboxes

We analyse your gearbox holistically.

This includes:

- Gear calculation

- Rolling bearing calculation

- Consideration of tribological aspects/ lubrication

We consider the complete drive train and the interactions (e.g. of an engine and a transmission unit). In the case of recurring problems or critical transmissions, we look for solutions. We analyse the causes of damage and contribute our many years of experience with various types of transmissions. If necessary, we look for solutions to improve your gearbox or develop a completely new gearbox.

We also design gearboxes and calculate the gearbox performance data (using Kisssoft software). This also includes a load simulation of the tooth geometries. The components are then tested on the in-house test bench under real conditions and compared with the results of the simulation.

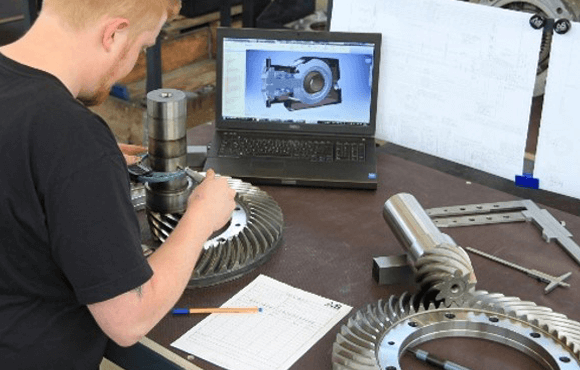

Measurement and recalculation of gears or spare parts

We measure complete gearboxes, gearbox housings and gearing parts and record them geometrically exactly. Based on the measured data, we create drawings and are therefore able to offer all components separately, even if the original drawings are not available. Reliable partners in our region then manufacture the parts according to our specifications. Measures for the acceptance of the components:

- Measurement of all components (also in 3D)

- Recalculation of the parts (if necessary)

- Creation of production drawings

- Creation of documentation

- Hardness test according to Rockwell, Vickers or Brinell

- Parts production with reliable suppliers