29 May 2015 Innovative direct drive in a turnkey-rebuild project at Mondi Dynäs (Sweden)

Ein Projektbericht

In October 2014, Mondi Dynäs (Sweden) produced Kraft Paper for the first time with the assistance of the newly direct drive FlexoDirect® in permanent magnet technology. Within this project, the AS Drives & Services GmbH modernized the complete drive technology of the PM6, together with the cooperation partner Kühne+Vogel Prozessautomatisierung Antriebstechnik GmbH and increased the design speed from 775 to 1,100 m/min.

The site Mondi Dynäs

The site Dynäs belongs to the international packaging and paper group Mondi and is located in Väja, Sweden. In Dynäs Mondi produces kraft paper on two paper machines (PM5 + PM6). The following project report describes the rebuild of the PM6. On this paper machine Mondi produces sack kraft paper with a basis weight ranges from 50–160 g/m2, a web width of 6,500 mm and a speed before the rebuild of 775 m/min. One target of this project was to replace the old mechanical and electrical drive and to install a new drive designed for a higher maximal production speed of 1,100 m/min. This drive was also to be designed in the way that a creeping speed of 15 m/min could be realized without any problems.

The drive of the PM 6 before the modernization

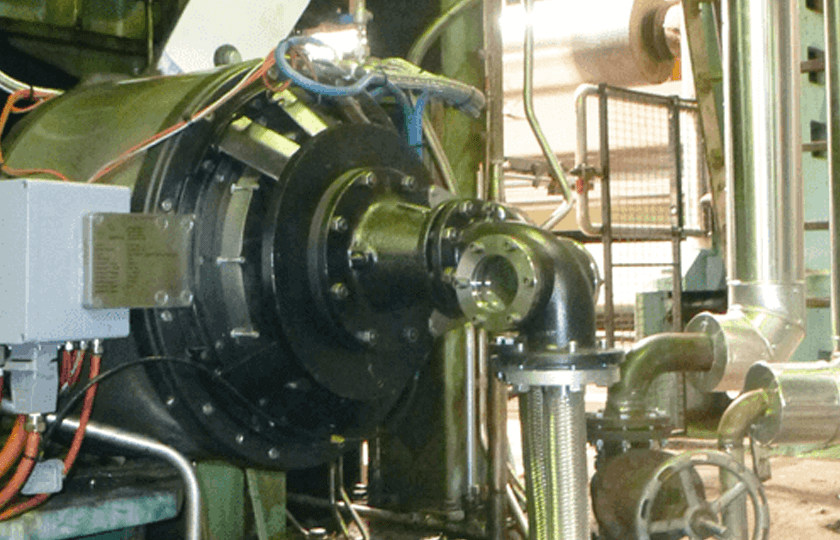

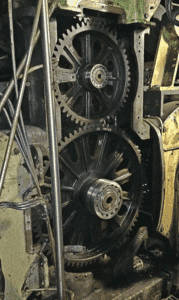

Before the rebuild at Mondi Dynäs, the dryer groups of the PM6 were driven by a closed wheel housing drive. This drive system consists of a central DC drive, which runs a number of down streamed intermediate and drive wheels via a drive pinion. The drive wheels themselves are connected to the cylinder journal and turn the dryer cylinder. (Fig. 1, 2)

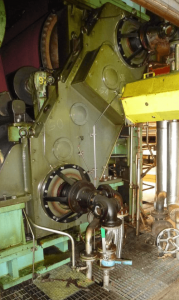

The high amount of tooth meshes between the wheels lead to enormous friction losses and to high wearout. Accordingly, the maintenance expenses are very high. On this principle, the mechanical drive system within the housing is influenced by high temperature fluctuation. The high amount of coupling points and the contamination of the complete internal space of the housing with oil makes the closed wheel housing drive difficult to manage concerning leakages. Besides the closed wheel housing, some groups of the dryer section of the PM6 were driven by a so-called DRG-gearbox. This form-fit gear unit is also driven by one central DC motor. Also, with this drive the torque of the motor is transferred via a pinion shaft to the intermediate gears and then to the drive wheels. (Fig. 3)

The difference compared to the closed wheel housing is that only the last two dryer cylinder of a dryer group were driven directly. Another difference is that the DRG-gearbox is outside of the machine frame. The felt carried the free cylinders along. This system could not solve the problems with the leakages and stress, but only shift them. Furthermore, the massive DRG-gearbox housing hindered the access to the cylinder bearings as well as to the machine frame. A changing of a cylinder bearing could not be handled in a day’s shutdown. For this project the susceptible DRG-drive, the old DC drives and the counter gearbox were uninstalled. The old closed wheel housing drive was eliminated by dismantling the intermediate wheels. The housing of the old closed wheel housing drive itself remained as a structural part of the machine frame.

The scope of the project (mechanical part)

AS Drives & Services (AS) was responsible for the rebuild of the mechanical drive components. Therefore, nearly all drive points of the PM6 were rebuilt or renewed, from the wet end until the reel. The company took over the engineering for the rebuild as well as the project and assembly management. The scope of supply included 20 standard drives, which come into operation in the wire and press section, at the Clupak and at the reel. For the

dryer section, AS delivered the self-developed newly hollow shaft motor FlexoDirect® in permanent magnet technology. Furthermore, AS delivered the technology which is necessary for the cooling of the FlexoDirect®. The cooling system consists of two cooling aggregates, Cooliflex® and 26 FlexoFlow®Water control devices, which

control the flow of the cooling water fully automatically in dependence to the motor temperature.

The new direct drive for the dryer groups

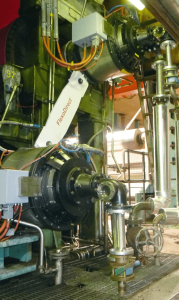

Conventional drive solutions for the dryer section (like at Mondi before the rebuild) often consist of one DC motor, which runs via a shaft one drive pinion of the closed wheel housing. Alternatively, the DC motor can be coupled to a gearbox which itself is coupled directly to the cylinder journal. At the so-called “silent drive”, several guide rolls are driven separately by motors and transfer the torque to the dryer felt. All dryer cylinders were driven by the felt. Normally various guide rolls per group have to be driven to provide the necessary driving force. The big disadvantage of this system is the high felt tension which is needed to drive the big dryer cylinder, as well as the small diameter and the small mass inertia of the drive rollers. In all conventional drive combinations the motor is located outside of the dryer hood. (Fig. 4)

At the turnkey project Mondi Dynäs, the innovative direct drive FlexoDirect® comes in use for the first time for the complete dryer section. This water cooled Permanent-Magnet-Synchronous-Motor (PMSM) from AS is the only drive solution on the market which allows the installation of the motor together with the steam head on the drive side. This is possible because the hot steam, which is needed for the drying, as well as the condensate can be led through the hollow shaft of the motor. (Fig. 5, 6)

The water, which is needed to cool down the winding, is provided within a closed circuit by the external cooling unit, the Cooliflex®. Compared to conventional drive solutions, the FlexoDirect® can be installed within the dryer hood due to the compact design of the motor. For the rebuild of the dryer groups of the PM6 in Dynäs 26 FlexoDirect® in sum with a torque of each 74–97.5 kW respectively 3100–4050 Nm (at a revolution of 230 rpm and a cooling water inlet of 65 °C) were installed. The FlexoDirect® provides the full torque even at standstill. Furthermore, the FlexoDirect® can absorb axial and lateral forces up to 22,000 N (e.g. from the steam head). A special challenge during the installation of this drive technology was the connection of the direct drive to the dryer cylinder journal. The journal length of the cylinders was not long enough. The cylinder journal ended with the bearing cover ends. In the pre-engineering AS therefore designed a modified bearing cover, which allows an insertion of the torque. An additional journal extension for the steam and condensate system completed the installation. In this way, the hollow shaft direct drive FlexoDirect® could insert the torque and take up the steam head. (Fig. 7)

Due to the patented torque support, a fixed connection of the FlexoDirect® to the machine frame is not necessary. All occurring reaction forces and tensions are not transferred in the frame. The torque support is designed in a way that occurring movements can be absorbed threedimensionally. For this reason the system is less liable to cylinder alignment compared to the traditional drive systems. Because of the high precise control of the FlexoDirect®, the torsional rigid connection and the elimination of the mechanical slack, Mondi Dynäs received a smooth and dynamic drive that is ready for the future. The elimination of all intermediary shafts, gearboxes and gear wheels also reduces the maintenance effort required for mechanical components.

The scope of the project (electrical part)

Kühne + Vogel (K+V) realized the electrical part of this project. A strategic partnership has existed between AS and K+V since 2013 on the drive sector for paper and board machines. Based on this cooperation, an extensive expert knowledge is available to customers in the sector of mechanical as well as electrical drive technology from one source. The resulting synergy effects were the significant arguments for the Mondi decision-makers in awarding the project. The electrical scope consists of the following parts in detail:

- Medium voltage transformers 6.3/ 0.69 KV L Switchboard WebDrive+/Paper to serve 47 drives, thereof

- 26 FlexoDirect® with SINAMICS S120

- Central air conditioning for the switch cabinet

- Engineering station WebDrive+/Paper

- On-site Touchpanels

- Control of the asynchronous motors and FlexoDirect® with WebDrive+/Paper function library.

An interesting challenge was to connect the existing DCS control system 800xA (ABB) with the SIMATIC S7 based WebDrive+/Paper–function library and to extend this system with the new drives. Furthermore, the electrical technology as well as the hardware and software engineering, the execution of an extensive FATs in Roth, the electrical installation, the startup and customer training were also scope of K+V. (Fig. 8, 9, 10)

Comments regarding the project

Jukka Linnonmaa (Operations Manager at Mondi Dynäs) commented on the course of the project as follows:

“Nearly all motors were exchanged and adapted to the new design speed. The precise control of the new drives leads to less paper breaks. Before the rebuild, the downtime was 5.56 days in sum until September 2014. The reasons were stoppages caused by the wheels inside closed wheel housing, DRG-gearboxes, paper breaks or problems with electrical faults. With the new drive technology we expect savings from more than 6 days over a period of one year. This exceeds all expectations with regard to downtime improvements. We also see enormous improvements by eliminating the old closed wheel housing drive. The maintenance expenses have gone down. Also, the oil demand has decreased because we only have to lubricate the cylinder bearings. The problems with the leakages of the housing of the old drive are completely gone. Furthermore, the noise has been drastically reduced. That makes the work at the machine for all involved much better and more comfortable. Over all, the project went very well. We have had no mentionable safety incidents and the expected additional production level is even better than expected. On October the 11th, 2014 we produced the first tambour by using the new drive technology. A big thanks to everyone involved for their cooperation.” (Fig. 11)