10 Oct 2010 Key project realized with FS Karton GmbH Neuss

The company AS Drives & Services GmbH (formerly AS Antriebstechnik & Service GmbH) has demonstrated that they are drive specialists with the project at FS Karton GmbH Neuss. The target of the rebuild was clear: increasing the line speed to 1,000 m/min.

To give you a few facts: In total 54 drives had to be renewed by AS. In the last stage of the rebuild alone more than 44 drives were dismounted and renewed by approx. 60 employees in four day and night shifts. AS took over the engineering, developping all the necessary steps for the rebuild and delivering all the gearboxes for this drive package. The motors were provided by other suppliers. Along the whole machine, all the bottlenecks to increasing line speed were eliminated. From the wet section to the rewinder, nearly all driving points were replaced. The roller drive, the rope winding for the coating roller, the board roller drive and the counter roller, everything was modified. To manage the assembly as quickly and efficiently as possible, AS was on site with the complete crew. Josef Alberding, Martin Bußkamp and Walter Ribbers, partners of AS International (formerly AS Group), were also on site members of this team as hands-on advisors due to their long experience in the assembly of drive components. The apprentices of AS Drives & Services GmbH also had the chance to be a part of the action. Currently AS is training 16 apprentices in the areas precision mechanics, mechatronics and technical draftsmen. The prospective precision mechanics and mechatronics got to know the processes on site and the technical draftsmen had a real look at what they will design in future. This cooperation was the basis of a classic win-win situation. The diligent assistants unburdened the skilled workers by doing easy tasks like handing over material or cleaning tools, loosening screws as well as dismounting old motors and gearboxes. After the motor consoles had been prepared for the new assembly, the new drive components could be mounted. The apprentices learned how to align a new gearbox or motor. They were impressed to see what the colleagues do on site. They also learned what all has to be observed when mounting a motor or gearbox correctly. The work has to be done precisely down to a hundredth of millimetre, even if the motor has to a total weight of several tons.

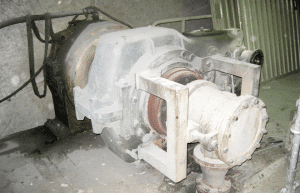

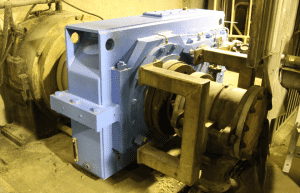

GearClone and Lubriflex®

In addition to the standard gearboxes a GearClone was mounted. The ClearClone was the biggest gearbox in this rebuild and drives the Yankee cylinder. The word GearClone describes the rebuild of a gearbox true to the original. This service package is usually offered when a gearbox is no longer available. In certain cases the GearClone is also cheaper than the original. AS records all performance data, calculates and constructs an identically designed gearbox. Sometimes smaller modifications are made, e.g. installation of new lubrication technology. With new technologies, the gearbox becomes even better than the original. The Gear-Clone of FS Karton Neuss is already the clone of a clone, as an identical gearbox of AS had been cloned before and is still running successfully in the sister plant in Gernsbach. In line with the GearClone, AS also supplied a corresponding oil lubrication system, the Lubriflex®. This system provides cleaned, degassed and correctly tempered oil. The Lubriflex® replaces the old central lubrication system in the cellar of the plant. With the help of a special degassing system the Lubriflex® needs only half as much oil as conventional lubrication systems. The project manager, Guido Brinkmann, had to keep the overview at all times. In the run-up to the project, the AS engineer had coordinated the tasks with the other companies on site. It was very important to work closely with the company which renewed the foundations for the motors to ensure a smooth mounting process. Apart from AS, about 350 additional employees of other companies were on site. Despite several shortages of crane capacity, the target of the rebuild was achieved without any problems. This was due in particular to the very good cooperation of all the companies involved and the FS Karton GmbH Neuss. On the fourth day, the majority of the AS staff could drive back home to prepare for the next service job. A small team stayed in Neuss, however, to ensure a smooth restart of all drives.