06 Jun 2020 A responsibility that weight tons

Reken, 06.06.2020

What is the fascination of the profession of precision mechanic? For apprentice Fabian Schroer, it is particularly the diversity and the daily confrontation with exciting challenges.

Fabian Schroer has always worked in his grandfather’s workshop as a little boy. So Fabian had already developed his manual skills at an early age.

Today, he is doing an apprenticeship as a precision mechanic in the medium-sized company AS Drives & Services GmbH in Reken, Westphalia, which repairs large industrial gearboxes, among other things. The dual training as a precision mechanic lasts a total of 3.5 years. Fabian is in his second year of training.

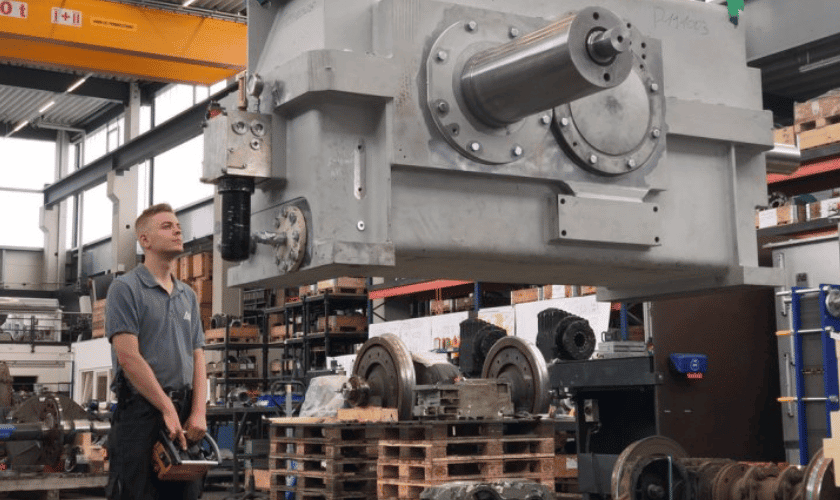

Already early in his apprenticeship Fabian was allowed to work on the big gears. And whenever it was possible, he went to the customer’s premises to reinstall the repaired gearboxes. The gearboxes are then installed, for example, in paper-making machines, in chemical plants or in cement works. The largest gearbox repaired at the Reken plant weighed 37 tonnes and was as big as a minibus.

Fabian first got to know the company through the school internship and later he did a voluntary internship during the summer holidays.

Skilled craftsmanship is crucial

The workshop master Rudolf Lienemann is convinced that this is exactly the right way. “Of course, school grades are also important to a certain extent when hiring trainees. For example, we attach importance to good grades in maths and the technical subjects. But what is more important is whether the trainees have manual skills and enjoy the job. In an internship, both sides, i.e. the student and the company, quickly learn whether it fits. In the end, the type of school is not important either. Our precision mechanic trainees come from Hauptschule, Gesamtschule and Gymnasium.

For Fabian, versatility plays a major role in his training. Often the number of gears to be repaired is “1”, so that almost every gear is a new challenge. After a basic training, where material and tool knowledge is taught, it is quickly put into practice.

Learning new things and exchanging experiences

Fabian also changes working place and can therefore always learn something new from his colleagues. He is also in good company. Because Fabian can exchange experiences with around 24 other trainees at any time. “That’s what makes the job so exciting. You see a lot, learn a lot and are allowed to take on responsibility for your trades at an early stage”.

“A special attraction of the training as a precision mechanic is also the future prospects,” explains managing director Heinrich Schrudde. “The lack of skilled workers and the good further training opportunities within the company make this possible. After completing the training, there is a good chance of being taken on directly. And there are also a number of further training opportunities. For example, you can become a master precision mechanic or technician or go to university to study mechanical engineering and continue to earn money while you do so. Training with a practical orientation helps enormously. We experience time and again that applicants who have first completed an apprenticeship and then continued their training are the more suitable candidates for our requirements.

Profound and varied training

The company has a lot to offer with its 130 employees. And anyone who believes that the profession of precision mechanic is taught exclusively in small, dirty workshops is mistaken. In addition to the classical training, Fabian learns everything he needs to do his job. To this end, he has recently obtained his forklift and crane driving licence. Now he moves the parts weighing tons himself.

Fabian does not yet know where his path will lead him after his training. “Basically I would like to stay in the company,” he says. But a part-time course of study is also conceivable.

This article was published in the Dorstener Zeitung