We’ll research for your added value

and develop the drives of the future

Our research and development department is dedicated to developing new electrical drives and the corresponding peripheral devices, and developing them further. We want to achieve real innovations and therefore added value.

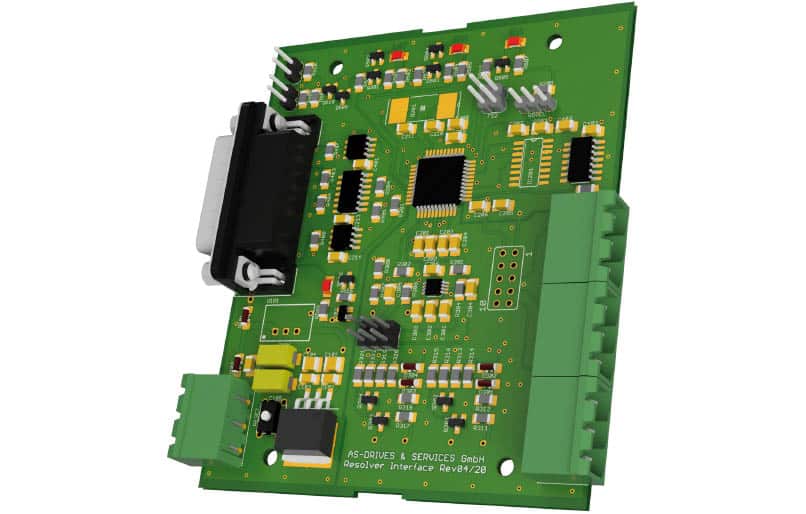

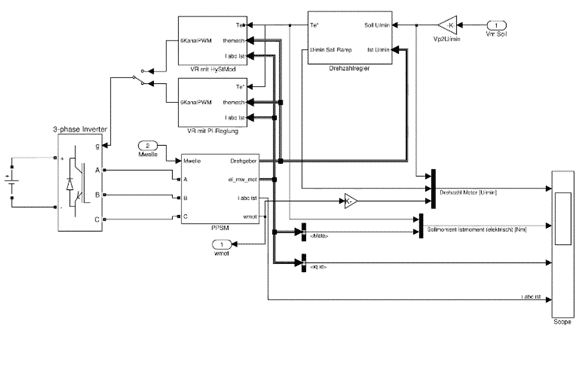

Hardware and Software

Many years of know-how in the electronic development sector enables AS to perform the entire process from conceptualisation and prototypes to series production, all from a single source. Thanks to machine-oriented software development, there is perfect interaction between the hardware and software.

- PCB hardware layout

- Software development (embedded systems, RealTime kernel, AVR, ARM, DSP)

- Programming in the languages C, S7, Python, Lua and LabVIEW

- Experience in designing and testing bus topologies (PROFIBUS, PROFINET, CAN, FlexoBUS, MODBUS), manual assembly of SMD prototypes and pilot series

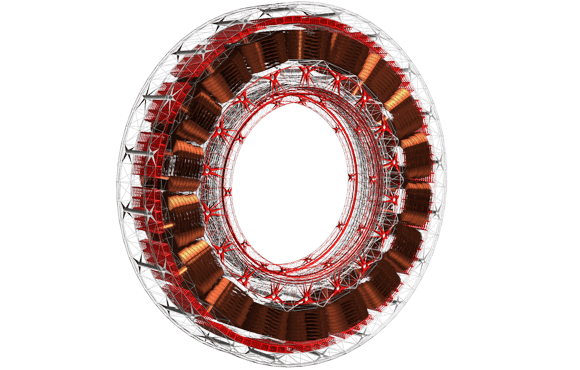

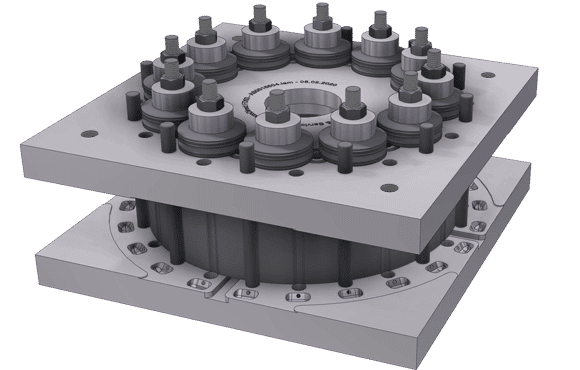

Electrical machines

- Analytical design of electrical machines

- Simultaneous engineering in 3D to produce and simulate all components

- Linear and non-linear calculations in 2D and 3D

- Analysing and optimising all relevant machine parameters (cogging torque, alternating torque, efficiency, thermal, operating behaviour on the converter)

- Our own tool design for prototypes and series production up to approximately 3t

- Laminating lamination stacks with a unit weight of up to 5t

- Winding with round wire and profile wire for single coils and coil groups

- Special winding for highly-loaded electromagnetic components

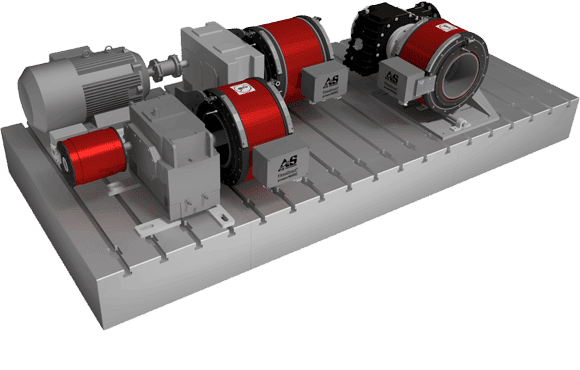

Device and tool building

- Test bench construction for low-voltage machines of up to 80kNm / 690VAC

- Measuring all parameters on our own motor and gearbox test benches (torque, power, temperature, vibration)

- Testing and analysing all low-voltage three-phase machines (measuring, testing)

- Recording all mechanical and electrical operating data using suitable equipment (PowerAnalyser, measuring flanges, vibration sensors)

CUT – CAM – CNC

- CNC turning, 4-axis CNC milling, CNC welding and soldering

- In-house CAD to CAM to manufacture our own test assemblies and prototypes

- Additive production in the FDM and SLA procedure

Multi-body simulation

- Multi-body simulation for mechanical, electrical and combined systems

- Designing, analysing and setting up mechatronic systems

- Layout and implementation of control systems

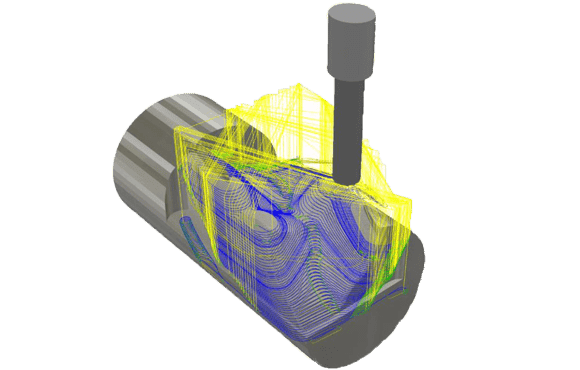

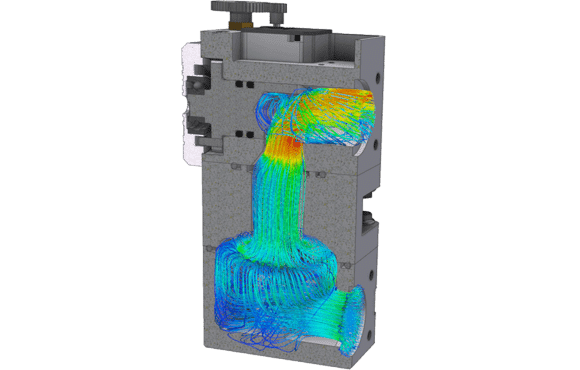

Computational fluid dynamics

- FD simulation to optimise complex component geometries such as valves and cooling systems

Insulation and winding systems

- Creating suitable insulation systems up to insulation class N made of organic and mineral insulation materials

- Test and test assembly for winding systems (high voltage, partial discharge, pulse response)

- Analysing and measuring permanent magnet systems (gyratory field distribution, axial in the 3D scan procedure)

Excellent co-operation with universities

- Know-how development and transfer

- Practical project reference

- Developing market-ready products

- Implementing promoted or non-promoted project contents